Hi Brent

I wish to design my own recumbent bikes and trikes in the future. In order to acheive this goal, my plan is to eventually graduate to cad programs like solidworks. Such cad softwares are not able to produce the handy mitering templates that BikeCAD can though, and I am trying to replicate those miter templates using trigonometry and matlab. The results I am getting though do not match up with the miter templates produced by BikeCAD. I am wondering if a reference exists desribing how BikeCAD computes the curves for a miter template.

Thanks for your help

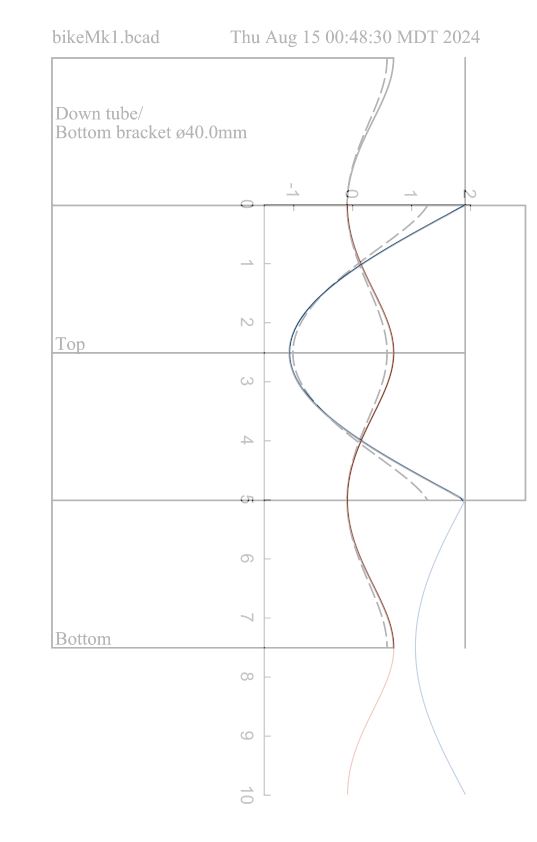

How close I can get

This image shows how close I am able to get. The miters on the other tubes match very well, but the compound miter at the bottom bracket, seat tube and downtube is still slightly off. The blue and orange traces were generated in matlab, and are laid over the bikecad miter output. I am not sure why the blue portion, which represents the compound miter on the dountube, is slightly off from what bikecad predicts. I am confused because I used the seat tube downtube angle provided by BikeCAD. I am wondering if their are details behind the seat tube downtube angle that I am not seeing.

It looks like I figured it

It looks like I figured it out, I just needed to shift the sinewave representing the miter for the bottom bracket down by subtracting an offset dependent on the radius of the seat tube and the sine of the angle between the seat and down tubes. It looks I have finally managed to replicate the miter template capabilities of bikecad in a matlab script, which may prove handy when designing a non standard bike in other cad software like solidworks.

Solidworks

Solidworks definitely can (or could!) generate these templates. Many years ago I used to use it to create the profiles to go on tube laser cutters when making tubing for racecar/kitcar chassis.

At the time you had to make each tube in the assembly as an almost complete circle (like a 359.9 degree arc), and then "unwrap" them to create flatform DXFs for the tube laser. It used the sheetmetal function.

I can't add much more than that as I no longer use Solidworks, and a lot of water has gone under the bridge since then - but it is, or should be, possible!