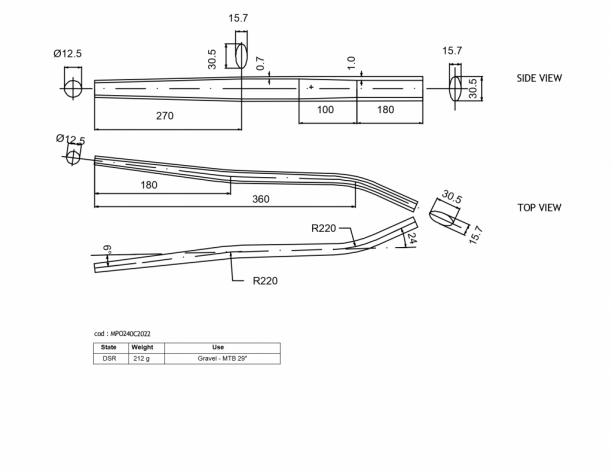

Hello, I'm always having trouble modeling prebent chainstays offered by many suppliers when I'm cutting up the chainstays to meet my desired cs length. I'm currently trying to use the deda cs tubes in the attached drawing.You can see that their drawings use both angle measurements (from method 2), along with radii and A/C measurements (from method 1) to the middle of the bends. If there was a 3rd method using this drawing style, I could subtract the length of my designed chainstay length from their numbers to get an offset and accurately model the chainstay bends in the right spot.

Or I'm an idiot and missing a completely easy way to model it. In real life practice, I've been using a cs jig I made to get the miter/spacing dimenssions at the BB and dropouts to match up correctly and using 3d printed guides to make sure tire and chainring clearence is ok.

Or even better yet, be able to model the chainstay/seatstays according to the design and having a slider left/right that just moves the design within your desired cs/ss length. That way you can position the bend exaclty where you need them quickly and easily. Also allows for saving different models of cs/ss in a drop down.

Thanks for the feedback, I'll consider this for a future update.

You can algo consider adding a static drawing template with code reference for tube suppliers, for instance, GX2650 from Reynolds and drawing would be iimediatly uploaded.

This would be a fabulous option, as would dropouts.